DLyte Technology

The DLyte machine combines grinding and polishing in a one-step process to produce smooth and shiny finished parts. It is used for metal parts which require high performance or superior finishes, including steel and stainless-steel, cobalt chrome, titanium, nickel and other common metal alloys. DLyte technology is the first dry electropolishing system of its kind, and the collaboration is set to have a huge impact the British manufacturing sector by reducing the polishing process time by around 75%. The new polishing concept will also dramatically improve the corrosion, oxidation resistance, lifespan and friction of a part.

Sid Gulati, operations director at ActOn Finishing, said the DLyte fits perfectly with the firm’s existing range of mass finishing products. He states: “We are very pleased to launch our partnership with leading Spanish engineering firm GPAINNOVA. We currently manufacture all surface finishing machines in the UK, and distributing the DLyte will complement our current offering as we look to grow the business. We are confident that through this collaboration we can offer an advanced process solution and help our customers overcome challenges in finishing their components. We look forward to distributing the finishing machine, and have already added the DLyte 100I to our test lab so our clients can try out the new technology.”

Some of the main benefits of the DLyte technology include:

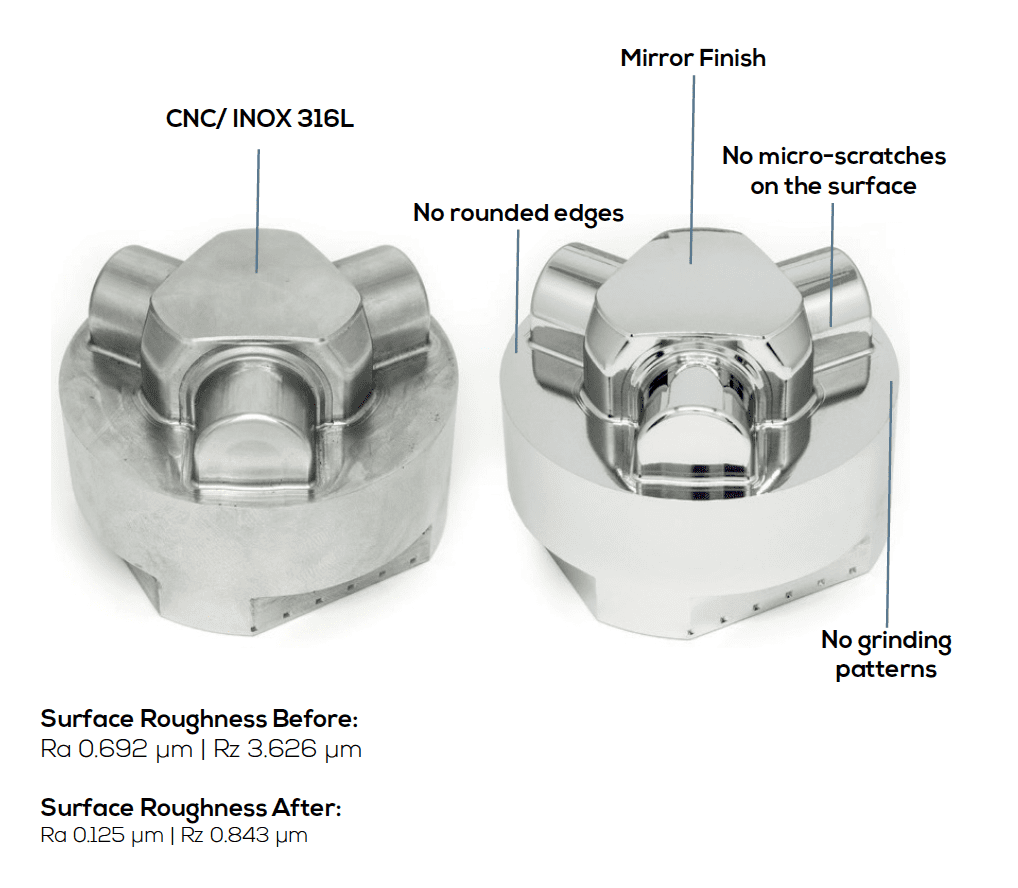

- The finishing machine can polish complex parts without programming, producing a high-quality finish without leaving grinding patterns and micro-scratches.

- It provides fully automatic polishing to a mirror finish in one step, and reaches every corner of the piece which cannot be accessed mechanically.

- Grinding and polishing of metal parts is an important process step for removing the defects in components, following the initial manufacturing process.

- It is especially important for high-precision engineering applications such as those within the medical, automotive and aeronautics industries, where surface quality is essential.

- DLyte is suitable for finishing anything from surgical instruments, industrial moulds and blades to engine parts, fuel injectors and guide vanes.

- Achieves an Ra under 0,09 micrometres

- Offers controlled costs and predictable lead times

Jaume Miras, chief strategy officer at GPAINNOVA, said that ActOn Finishing fits perfectly with the firm’s sales partnership expansion strategy for mass finishing products. He states: “We are very pleased to increase our presence in the British market with an experienced and leading expert in surface finishing as ActOn Finishing.”